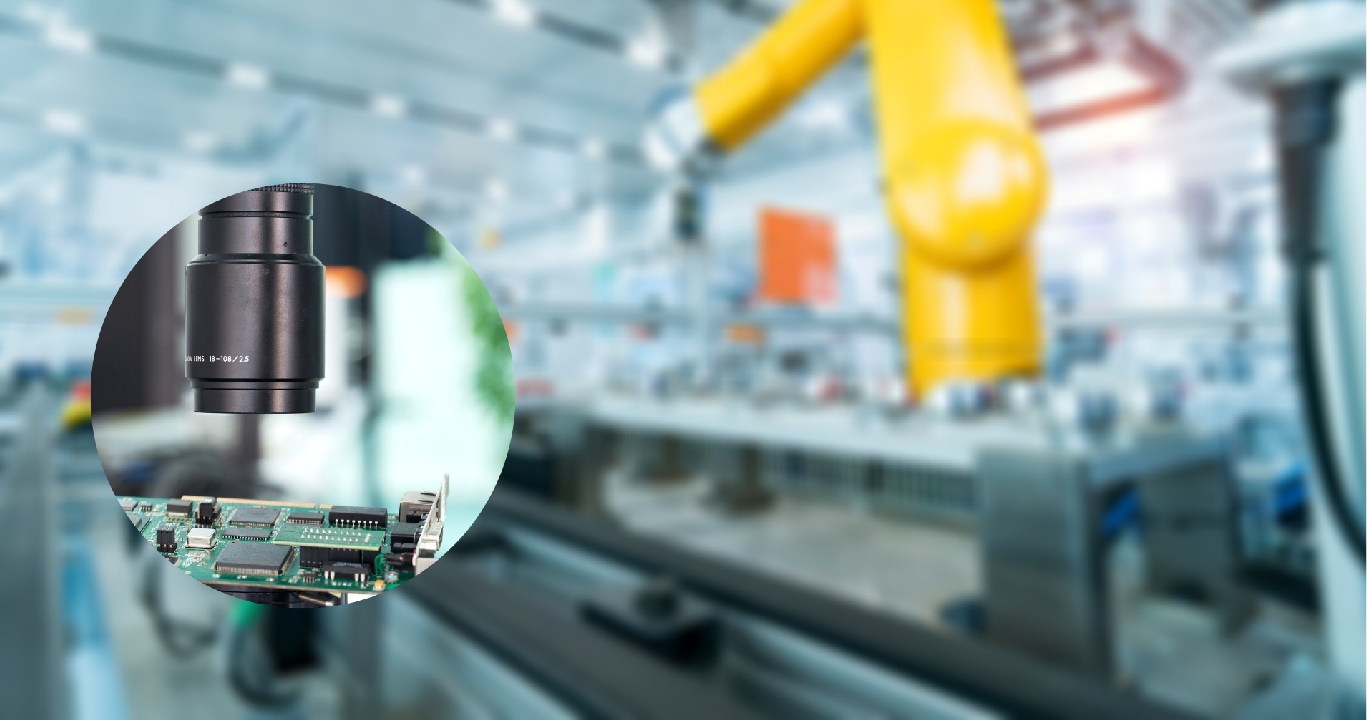

With the help of cameras placed at strategic locations in the manufacturing line, machine vision helps in minimising wastage. More and more companies worldwide are adopting it to improve their metrics. Reduced wastage in manufacturing companies is one of the many uses of machine vision. Here are a few types of wastage created and how machine vision helps in reducing them:

Defective products due to poor quality adding to time and resource wastage

Quality control is automated, thereby helping detect faults in real-time. Earlier, it used to be accomplished in batch processing by humans which used to be time-consuming and prone to errors. Overproduction in the beverage industry due to the defective pieces also being counted led to a false information on metrics, also leading to further processing time to rectify the defective ones, thus cumulatively draining the resources in addition to spending more time on the same output.

More reliable and precise, better wastage detection leading to improved metrics

Machines can now make decisions based on the data captured in scanning. This is based on a whole lot of base data that is fed into the system as the ideal for comparison. Machine vision is much superior to human vision, leading to more dependable and precise data being captured and used. Machine vision works 24×7, thus helping detect and reduce wastage on a larger scale, improving the throughput many-fold.

Better control on wastage in injury-prone industries

Manpower safety is improved as machine vision helps in critical and hard-to-reach areas, thus helping manpower deployment in safer operations. Food industry is one such where not only does machine vision achieve precise cuts, it improves the safety level of operations while reducing wastage and improving productivity at the same time.

Conservation of the environment by controlling wastage of natural resources

The wood industry has benefited immensely by the use of machine vision. Not only does it help in greater precision by ensuring properly sized planks and lesser wastage, it also creates actionable data such as the reduction in thickness of boards or thinner blades to be used for cutting all of which helps management reach more productivity with less wastage of the raw wood logs. This has the added impact of conservation of this vital environmental resource.

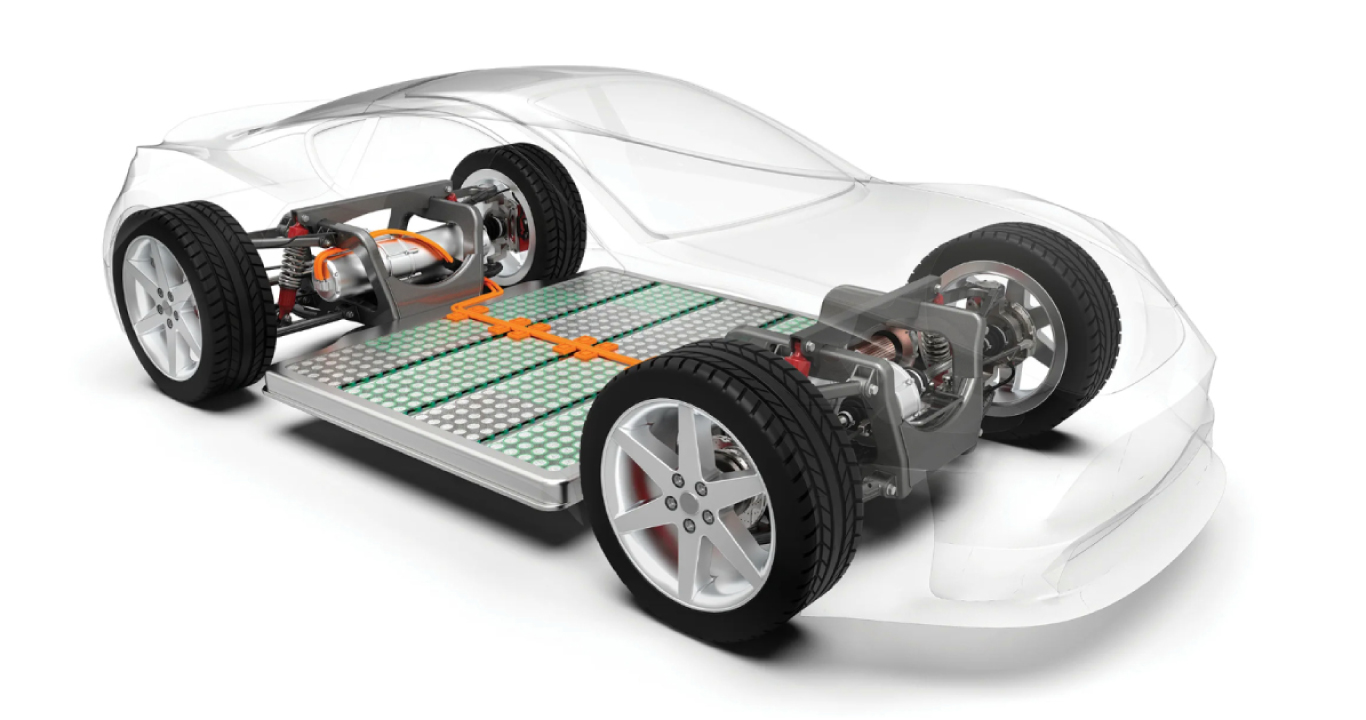

Improved productivity in equipment manufacturing

Reduction of waste is one of the most effective ways to increase the profitability of business. Machine vision provides vital information about the plant floor and exact location of a manufacturing line where there is scope to reduce wastage and improve. Understanding where the wastage is helps in reducing its effect on productivity, overall performance and quality in large manufacturing units. Lean Manufacturing is achieved using machine vision.

No wonder, machine vision is being adopted by more and more manufacturing companies in today’s competitive environment.

Please visit www.melss.com for a complete list of solutions we provide.