Skilled manpower need no longer be utilised in repetitive and mundane jobs, and can now be used in higher value tasks such as engineering and maintenance. Repetitive jobs are best handled by robots which also result in more throughput and efficiency. Precision handling eliminates many an imperfection in human handling, delivering higher quality. Also, moving manpower away from hazardous roles which can be handled by robots improves the safety level.

Here are just some of the ways in which robotics results in higher efficiency and lower manpower dependence. (5 ways in which robotics helps to increase efficiency and reduce manpower)

1. Repetitive Jobs Are Handled Better

Volume production often requires the same operation to be carried out at fast intervals, and this is best accomplished by robots. This helps industries achieve quicker turnaround time. The speed of operation is also attributed to robots nullifying human errors, and the time taken to complete each task is reduced. Precision is guaranteed by using robots. Besides, for ease in operations robots are deployed to handle components of complex jobs, such as lifting heavy loads and picking.

2. Metrics Are Maximised

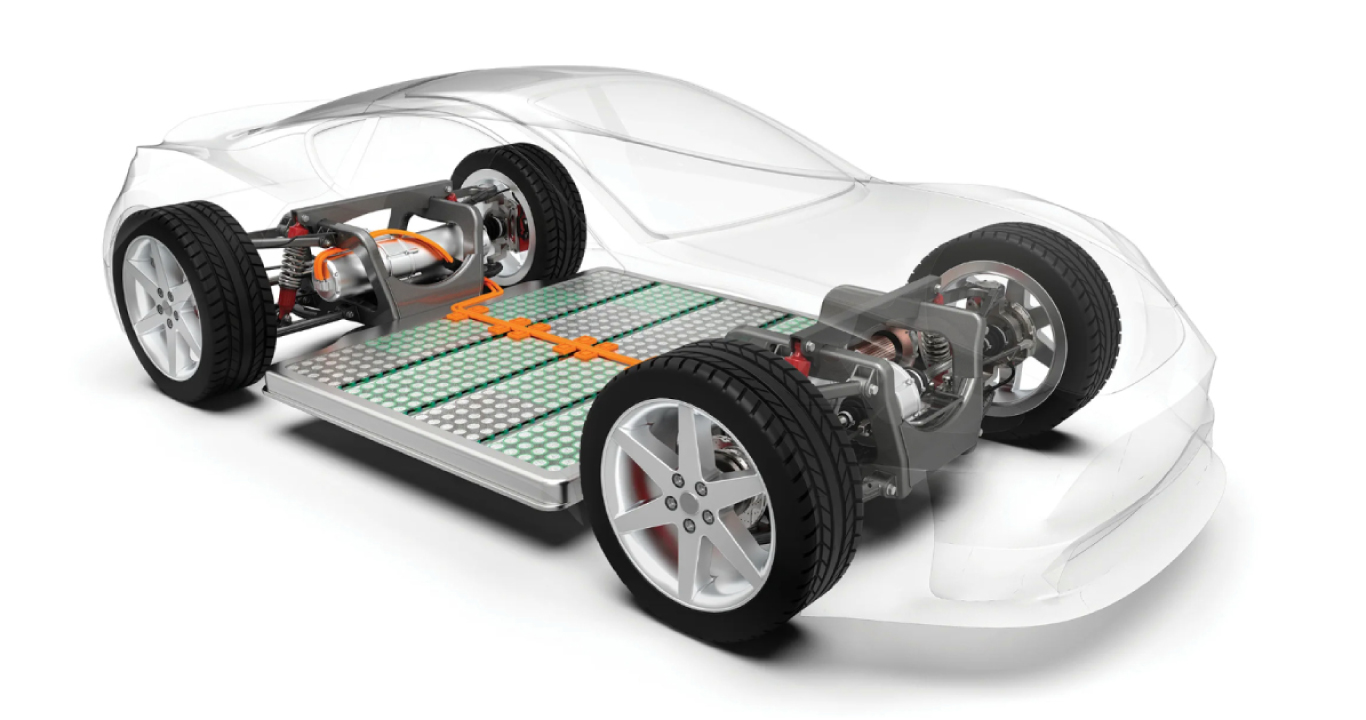

A category of manufacturing where robots are being used exhaustively to improve efficiency is automobile manufacturing, calling for treatment as a special category for discussion. Each stage of automobile manufacturing has adopted robotics. The stamping stage which was earlier prone to human injuries, or even fatalities, has embraced robotics thereby eliminating the need for manning by humans. The body shop department uses robots for welding and punching. Assembly lines increasingly use robots helping to deliver world-class models.

Not only this, alternate handling of models is now possible, by programming the robot to handle that way, adding a new dimension to the whole manufacturing process. The latest models of most automobile majors have minimal involvement of humans and maximum involvement of robots.

3. Perfect Precision Is Now Possible

Miniaturisation is the norm in electronics manufacturing. Each unit is made up of smaller components which also need to be picked and placed precisely. High precision in operations is mandatory, and robots are a necessity. Mass production is needed to remain competitive without compromising on quality. Robotics plays a major role in achieving that. Efficiency and precision are increased with reduction in human participation.

4. Uniformity in Production Is Achieved

Healthcare industry requires help in various stages to ensure uniformity in batch production. Assembly after proper picking and placing resorts to robotics. Controlled and repeatable movement of the robotic arms ensures zero spills. Assembly inspection by in-built camera ensures zero errors and uniformity. Palletising robots help move human participation away from risky lifting operations. Proper labelling and printing are accomplished by the ever-so-efficient robots.

5. Safety to Manpower Is Ensured

Technological advancement to improve strength of materials has led to various industries using composite materials in the manufacturing process. Manufacture of composites is often in hazardous environments and deployment of robots helps reduce health issues. Also, composites are created with the same composition, time after time. Often requiring force, humans need breaks in between but a robot delivers the same quality 24×7 thus increasing efficiency.

Replacing or supplementing manpower with robots not only increases efficiency but is cost-effective in the long run and has many indirect benefits too such as being environment-friendly and adaptable to all-weather conditions.

MELSS delivers pioneering solutions in robotics to different industry segments, cobots (collaborative robots), end-of-line components for robots such as grippers, as well as highly reliable maintenance and service support. Click here to learn more about our robotics solutions – they could be exactly what your manufacturing facility needs.

For a video about types of Industrial Robots and their applications click here.