With Printed Circuit Boards (PCBs) being omnipresent in most equipment we use today, the importance of soldering cannot be overstated .

A PCB includes Through Hole and Surface Mount components. Hand soldering and robotic soldering are used for through hole components while wave soldering and reflow soldering are used for surface mount components. Robotic soldering is now being used to replace the time-consuming hand soldering. Reflow soldering is the commonly used technology for surface mount components which also uses wave soldering.

Soldering for SMT components

Reflow Soldering

In reflow soldering, solder paste composed of flux with soldering beads suspended in it is applied on the PCB using a stencil. Tiny SMT components are then placed on the board using a robotic pick-and-place machine. This board is then passed through a reflow oven with different heating zones suiting respective applications where the solder paste melts and then solidifies to keep the tiny components in place. The larger components and through hole components are soldered using hand soldering separately.

Wave Soldering

In wave soldering, the PCBs pass through a wave of molten solder. The underside is sprayed with flux which evaporates before the board passes through the different types of controlled molten solder waves – for boards containing both SMT and through hole components, the underside containing SMT components passing through the solder waves while the top side contains the through hole components for hand soldering or robotic soldering.

Soldering for Through Hole components

Hand Soldering

Many components such as batteries or odd-shaped parts that cannot go through either of the above methods need hand soldering using a solder wire with flux core. IPC standards need to be adhered to while soldering. Hand soldering is helpful in customised connections but it needs trained hands. Many tools are available which aid in hand soldering and help in consistent and precise joints.

Robotic Soldering

Robotic soldering on the other hand uses programmable robots to speed up the time-consuming hand soldering process. These robots not only are programmable but aid in repeatable soldering, improve the quality of solder joints, and what’s more work 24×7

thereby increasing the efficiency of soldering. These robots can be used both as standalone or in assembly lines.

Addressing the needs of soldering, MELSS brings you soldering materials and equipment from the pioneers in the field:

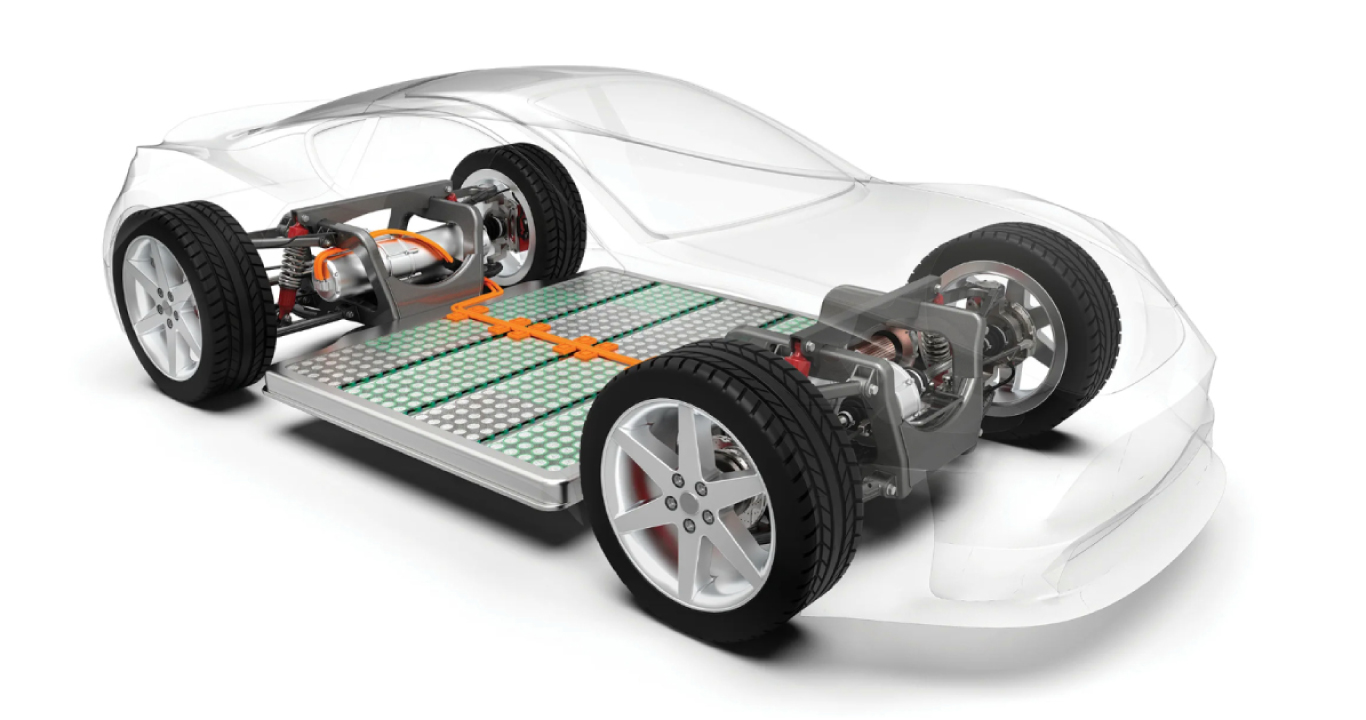

- The widest range of solders and fluxes from Indium Corporation including the suite of low-voiding solder pastes, reliable solders for e-Mobility and the patented Durafuse LT

- Cleaning chemistries including those for PCBs from Kyzen

- Dispensing Systems from TECHCON for accurate dispensing of soldering solutions

- Soldering and fume extraction solutions from METCAL including such path-breaking innovations such as Smartheat technology for fixed temperature soldering applications besides for the variable temperature soldering applications.

- The indigenously built Soldering Robot, Solderbot which comes with many unique features such as pinpoint precision, user-friendly programming, online monitoring, and speed. It also has 0.05mm repeatability and performs drag soldering leaving no mess.