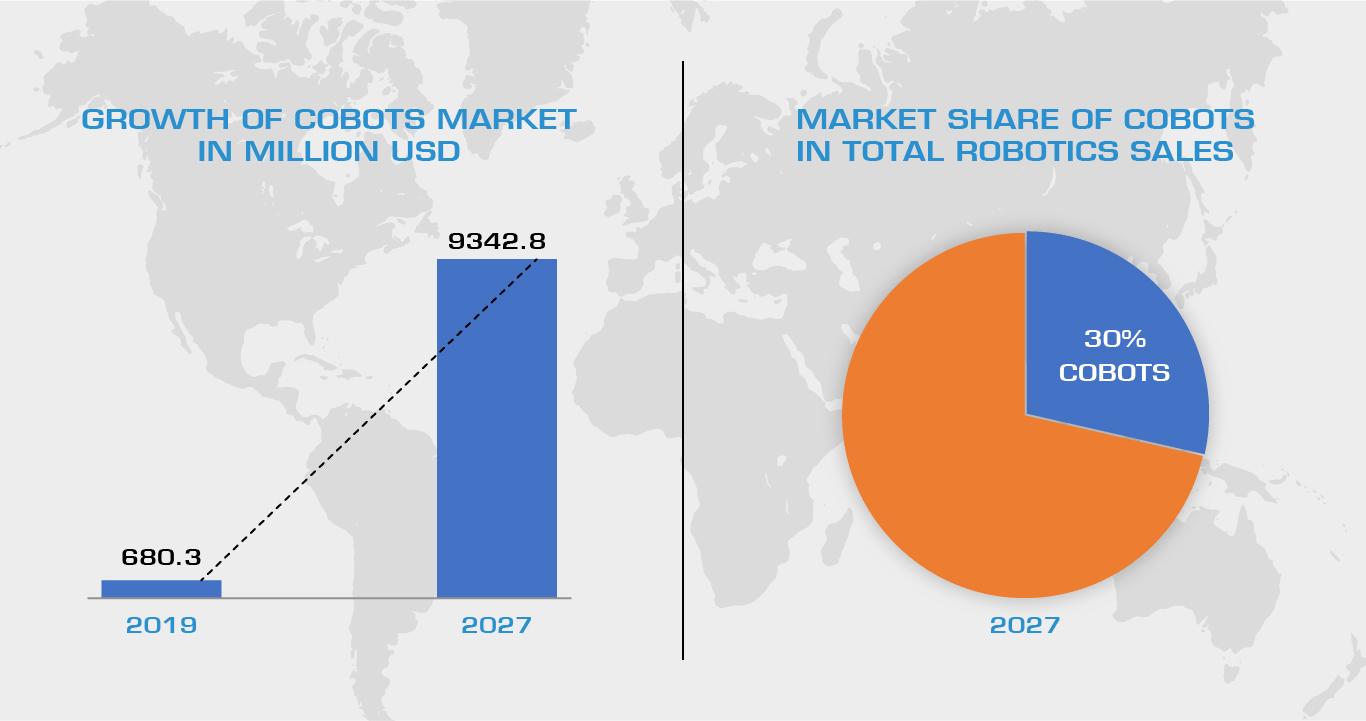

According to emergenresearch.com, the Global Cobots Market is forecasted to grow at a rate of 38.5% from USD 680.3 Million in 2019 to USD 9342.8 Million in 2027.

This is against the backdrop of a growth forecast of USD 45.1 Billion in 2020 to USD 77.4 Billion in 2025 at a CAGR of 11.4% for Top Industrial Robots.

Cobots are driving the growth in the Robotics Market and according to Interact Analysis, cobots will account for approximately 30% of the total robots market by 2027.

With the advent of automation and IIoT (Industry 4.0), many large-equipment manufacturers have adopted robotics in a big way. Earlier, only those manufacturers who had a large floor space to install robots with the requisite safety measures and who could justify the ROI went ahead with adopting robotics. All this has changed with the creation of collaborative robots (cobots). By being able to be deployed alongside humans across different manufacturing lines, cobots have contributed immensely to Industry 4.0.

Not only have cobots brought robotics within the reach of even small-scale manufacturers, but they have also been welcomed by the workforce who can now work alongside cobots. The goal of automation is achieved with quicker turnaround and ROI; all this with utmost precision and efficiency.

COBOT Market by Industry

Electronics

Currently the cobot models handle payloads from below 5 kgs to above 25 kgs, giving them an exclusivity in low payload models which occupy less floor space and are very economical. Cobots are ticking all the boxes for the electronics industry with an accuracy of 0.1mm or less, ideal for handling delicate PCBs alongside humans. The cobots market is projected to grow at the highest rate for the electronics industry.

Manufacturing

However, in terms of market share, handling applications will hold the largest share. Industries will continue to benefit from the applicability of cobots to repetitive tasks such as pick and place and palletising. Cobots can be placed in close proximity to other machines such as CNC for machine tending, as also near despatch conveyors for packing and palletising. Performing automation tasks with ease, these cobots have helped move the workforce to more meaningful roles while at the same time improving efficiency, productivity and quality.

Automotive

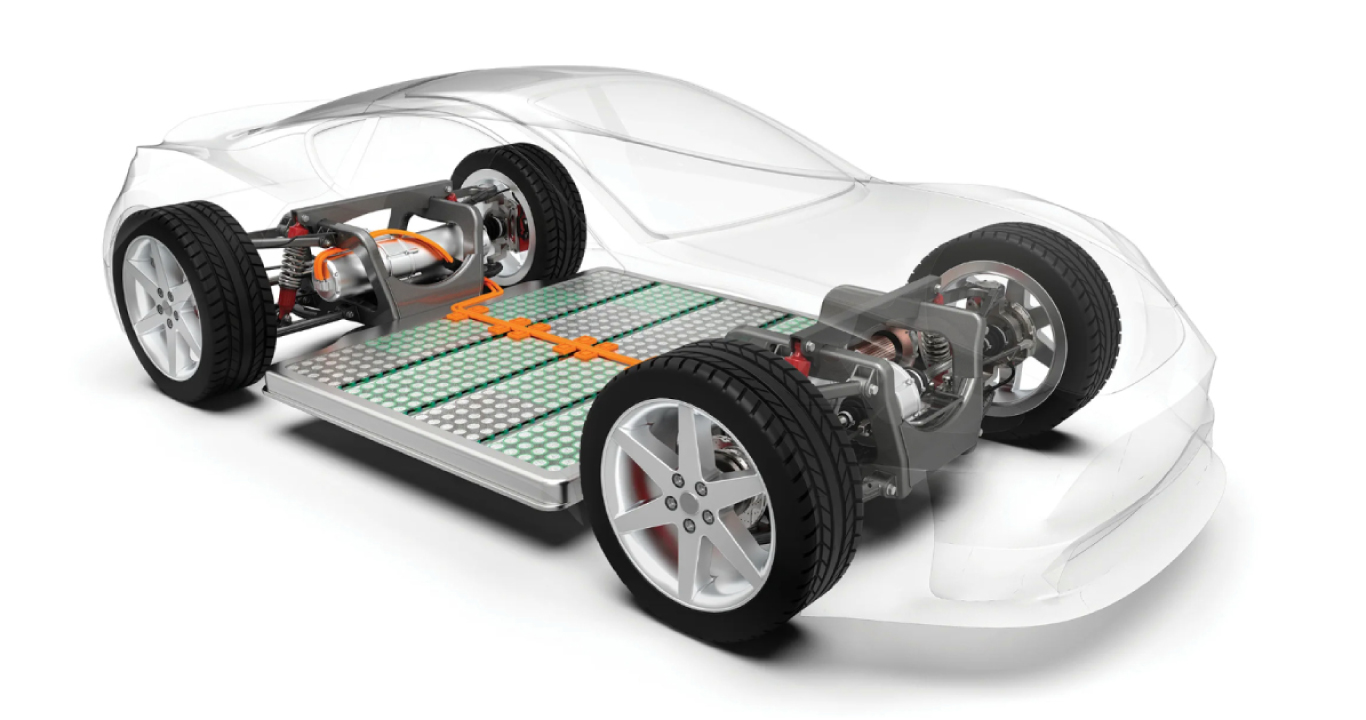

The earliest adoption of robotics was in the automotive sector which employed robots. But with the advancement of technology and the emergence of cobots has ushered in robotics at a much larger scale, with cobots helping in the body shop in welding activities and specialised applications such as screwdriving, in paint shop and in assembly lines.

FMCG

The FMCG sector is increasingly adopting cobots with manufacturing lines in cosmetics, toiletries, beverages and food processing gaining from the collaborative robots. Not only are cobots able to work alongside humans, but they are also improving human experience with food vending and preparation in kiosks and restaurants. With appropriate EOATs, they are helping churn out more hygienic products which are untouched by hand.

Healthcare

The healthcare sector is witnessing an increasing adoption of cobots to help improve patient care; the more routine nursing tasks are carried out by cobots while nurses focus on the actual patient needs. Cobots are helping diagnostic services in handling and sorting of samples. Surgeons, nurses, therapists and assistants are benefiting from the collaborative nature of cobots.

Cobot Market by Component

While the hardware is growing at a brisk pace, the software component is growing at a high rate too. Cobots have made a mark with their easy programmability. Various software tools have forayed into the cobots market adding to their easy setup and quick redeployment. Riding on this growth, End-of-Arm-Tooling (EOATs), which lend flexibility to a cobot, have shown significant growth.

Cobot Market by Geography

While currently the APAC region is dominating in the number of installations worldwide due to the quick ROI offered by cobotsand also due to the huge electronics industry in this region, subsequent years may witness a shift in the balance towards Europe which is adopting cobots due to their inherent safety features.

Although a late entrant, India as a global manufacturing hub for automobiles, electronics and medicines has been witnessing a greater adoption of cobots and will continue to do so in the future.

Robotics, which was earlier the privilege of a select few industries, has now been adopted across a wide range of industry segments and even in research, thanks to the flexibility offered by cobots.

MELSS has been providing many solutions for Industry 4.0, and brings you cobots from the leaders, Doosan Robotics and EOATs from OnRobot. With an experience of more than 25 years across industries, MELSS provides solutions in robotics based on your requirement. For more: https://www.melss.com/latest/industry-4-0/cobot/