Ever since 1995, collaborative robots (cobots) have helped to spread robotics into many industrial segments which were earlier not considered due to concerns regarding prohibitive cost, space constraints or safety and operability issues.

Even when available, a cobot is often not properly utilised. The type of cobot selected could be incorrect for an application due to the limited range of cobot models and lack of awareness of requirements. A knowledgeable manufacturer of cobots is needed who offers a wide range of solutions suiting your specific application needs.

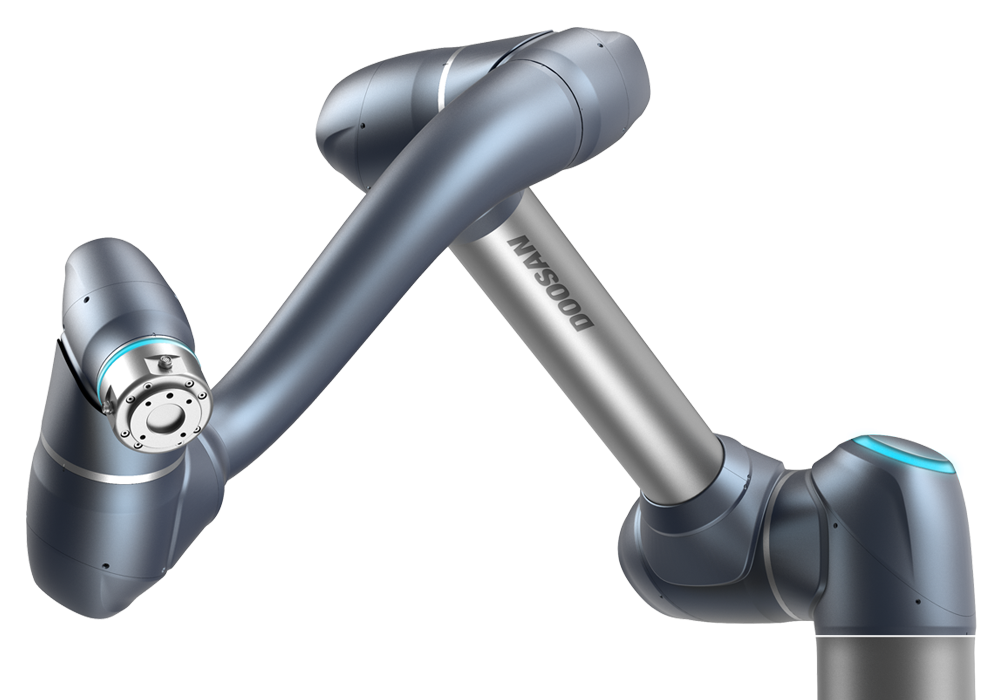

Doosan offers a wide range of cobots which can be used across applications and industries.

Why Doosan?

Within a span of 7 years, Doosan has captured 7% marketshare worldwide and is backed by the diversified 125–year legacy of the Doosan Corporation.

It has been researching the need for cobots and has been innovating by creating world-class cobot models with cutting-edge features. No wonder, it has been embraced by diverse industries. Doosan‘s innovations include:

Highest safety for operators

Operator safety is of utmost importance when it comes to cobots. Doosan’s H-Series boasts of the highest collision sensitivity in the industry, with six high-tech torque sensors. With Safety features that include Emergency Stop, Safe Torque Off (STO), and Safe Brake Control, a secure and safe work atmosphere for operators is ensured. The functional safety of the Doosan H-Series collaborative robots is certified as PL e-Cat 4 in accordance with ISO 13849-1. These cobots also feature a counterbalance mechanism to ensure their own safety, whereby the light-weight hardware reduces shock to improve the safety.

Zone-based operation

Each Doosan Cobot can be set into various zones according to the site application – Cooperation, Jam Prevention, Collision Sensitivity, Limited Tool Orientation and User-defined Zones. This ensures that the collaborative robot can work safely and efficiently alongside humans.

Highest payload capability

The Doosan range of collaborative robots can handle many payloads, and the H2515 boasts of the highest payload in any Cobot, easily handling up to 25kg payloads. Lower payload models in the H, M and A series are available depending on the application.

Flexibility

The Doosan H-Series cobots are very flexible due to their lightweight design which allows for free movement, flexible work settings and easy coupling with mobile robots such as AGV and AMR.

Applications

Doosan cobots find wide applicability in the manufacturing industry in applications such as Pick & Place, Assembly, Packaging and Palletising, Press Forming, Glueing and Bonding, Inspection, Injection Moulding, Polishing and Deburring, Air Blowing, Machine Tending and Heavy Object Handling.

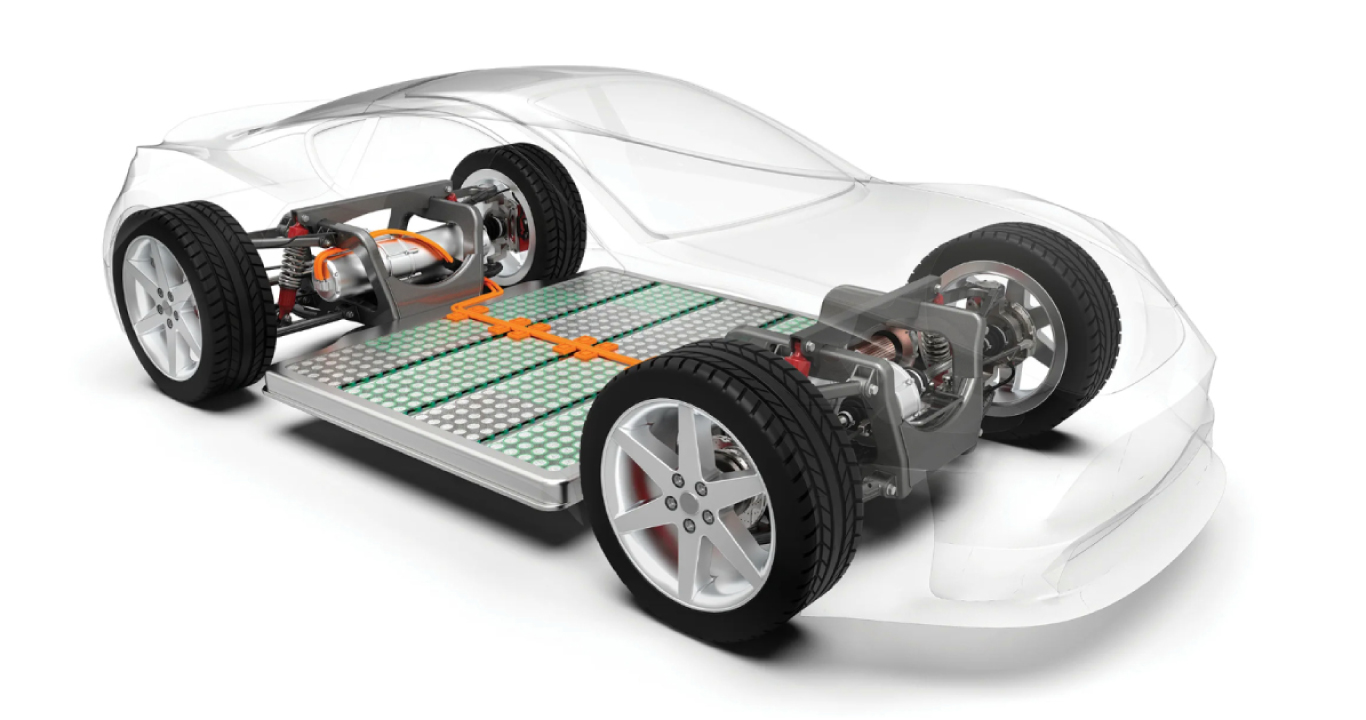

Not only this, they also find applicability in the Service Industry in applications such as Food and Beverage, EV Charging, Video Shooting and Medical.

Common features

All Doosan cobots can be programmed by easy-to-complete, one-touch programming to automatically detect attached peripherals and suggest ideal work processes. On the operator’s side, it is easy to learn even for beginners. The in-built cockpit is handy to quickly and easily teach robots.

Compatibility

Doosan Mate comprises a variety of industry-leading partner products compatible with Doosan to provide the best automation solutions, optimised for customer needs.

Connectivity

Doosan cobots are capable of being connected even without a gateway, making it easy to interface with various types of industrial equipment and systems.

*Supported Communications: RS-232, RS-485, TCP/IP Socket, Modbus-TCP/RTU, PROFITNET, EtherNet/IP

Accessories

What’s more, it also comes with many user-friendly accessories such as

- Mobile Base

- Smart Vision Module

- Protected AC Controller (CS-01P)

- DC controller (CS-02)

- DART-Platform

- DC controller (CS-04)

- Teach Pendant

- ROS support for various platforms such as Windows and

- Amazon AWS Robomakers

There is also a provision for Doosan ROS package

Continuing on the path of innovation, the Doosan Robot Controller can be connected to a Visual Components 4.7 model to visualise its utilisation in any industrial space which results in more productivity and profitability for the industry.

MELSS brings you the whole range of Doosan collaborative robots comprising the A, M and H Series, also including the E Series for the F&B industry. For more information on how we can help you automate with Doosan cobots, please visit: www.melss.com