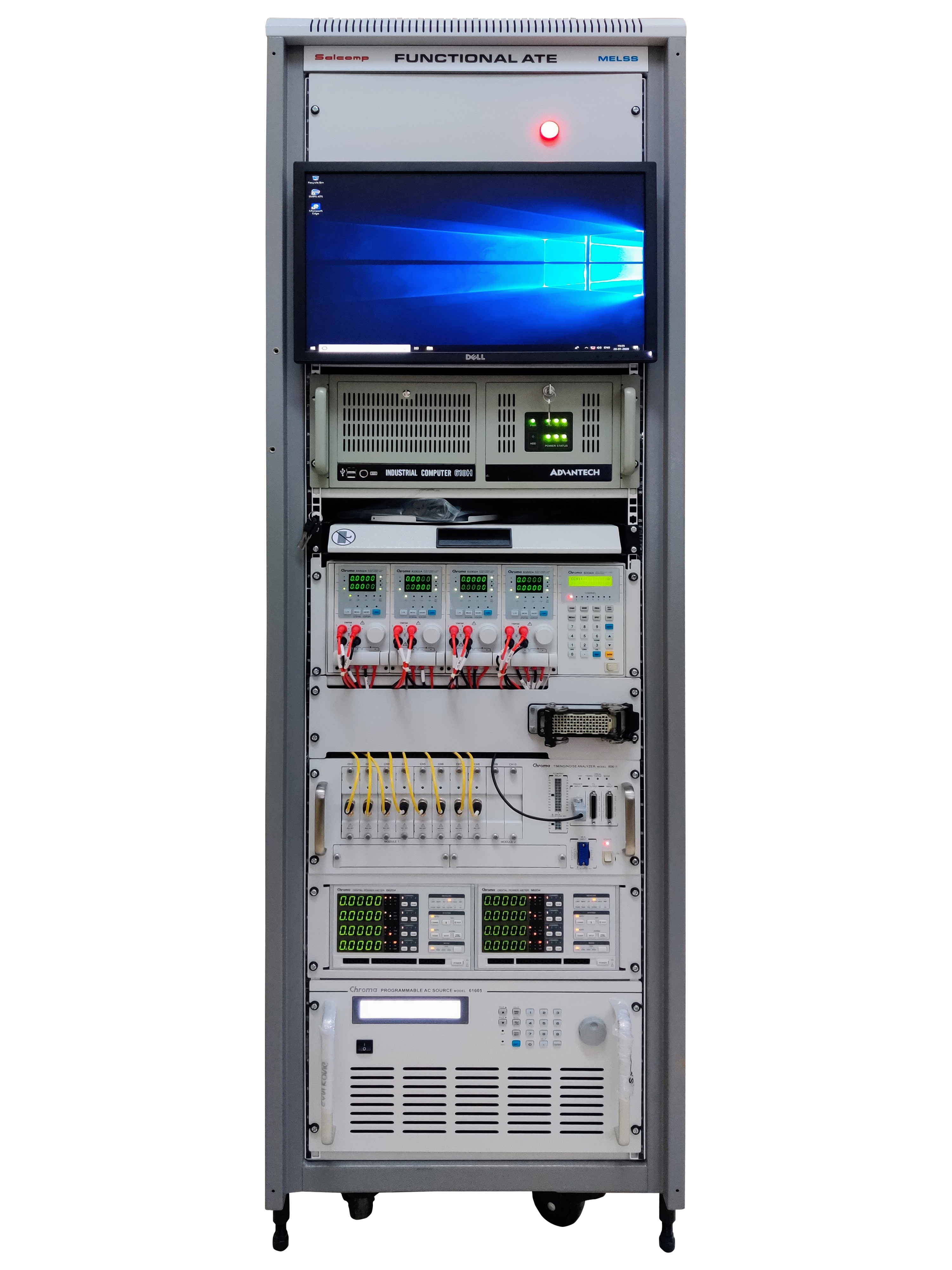

PCB Functional Test System

Ensuring defect-free products has been a critical success factor for any organisation. Various technologies have been implemented to identify defects at PCB level. This includes inspection, manufacturing defect analysers, boundary scan testing and in-circuit testers.

For identifying the manufacturing process related defects, the industry has a strong preference for in-circuit testers as they provide the highest possible fault detection among all the technologies. Modern generation in-circuit testers include other test technologies as part of testers, like boundary scan tests, MDA functions etc. With the increase in high-density PCBs and reduced real estate for test point and access, the ability to acquire interconnections between the tester and PCB has been progressively reduced.

Functional tester is the gate-keeper that allows only fully working boards to be shipped out of an assembly line. The tester looks at the whole PCB and not at individual components. It simulates the functions of the boards and compares it to the expected operation of the board as per the design with allowance for minor design variations.

MELSS has decades of experience in design, development and implementation of functional testers both as a system integrator and also as a distributor.

MELSS has worked on various partner products for building functional testers including Agilent, National Instruments, Chroma and Adlink.

MELSS also distributes, implements and supports PCB functional test systems from M/s Teradyne.

Functional testers have the following major sections:

- Control hardware

- Power supply & distribution

- Test & measurement instruments

- Switch matrix

- Software

- Fixture/interface

Functional tester has an independent test strategy to test and identify functional workings and deviations in the following types of PCBs or sections of PCBs:

- Power supply

- Digital sections

- Analogue sections

- Mixed signal

- Communication/interface test

- Display test

- RF test

- Boundary scan tests

- PCB – open/short tests

The instruments used can vary from the standard box type to the card type. Generally the following instruments are used:

- Box type instruments with USB/RS-232/Ethernet and other interfaces

- PXI/PCIe/PCI instruments

- VXI instruments

- LXI instruments

Software used for implementation is:

- Microsoft Visual Studio

- Microsoft .NET

- National Instruments LabVIEW and TestStand

- Teradyne CSi instrumentation

MELSS also has extensive experience in upgrading old ATE systems and re-hosting programs to the current generation of testers.