Optical Test Systems

What does optical testing bring to the table in terms of manufacturing? Precision, accuracy, control, speed, and the ultimate test of performance.

The Need

Optical testing systems are being deployed by varied industries for different applications including in the field of research and development, communication, engineering, academics, manufacturing, and so on as they literally throw light on device quality, performance, and flaws.

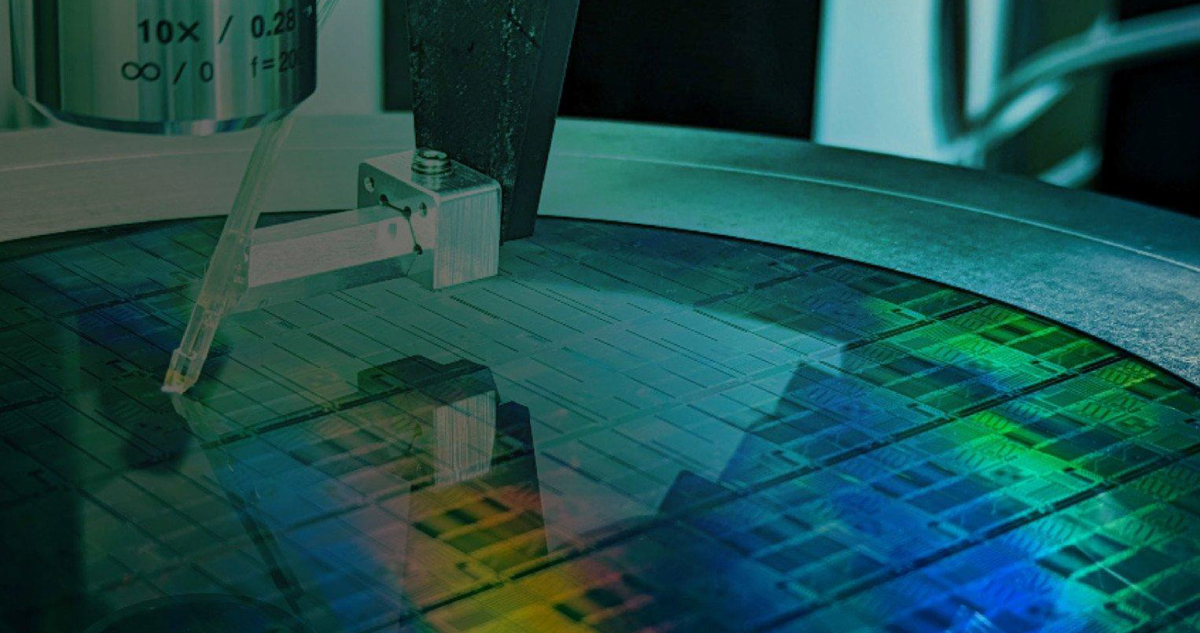

The global demand for optical testing systems is primarily driven by the increasing demand for improvised accuracy. During manufacturing, optical testing helps to increase yields by testing to validate performance thereby reducing overall costs and increasing the overall efficiency of the manufacturing process.

The global demand for optical testing systems is primarily driven by the increasing demand for improvised accuracy. During manufacturing, optical testing helps to increase yields by testing to validate performance thereby reducing overall costs and increasing the overall efficiency of the manufacturing process.

Optical techniques are critical to the manufacture of diverse and basic products such as semiconductor chips, aerospace, roads and tunnels, construction, and chemicals to make equipment robust and reliable.

Optical testing and measurement systems are used in various application areas outside of industrial manufacturing processes as well such as architecture and design (to optimize shapes); forensics (digital reproduction of injuries); agriculture (to better understand sustainability); and natural sciences (analysis of surfaces and motions).

Drawbacks of Conventional Testing

Conventional testing and measuring processes are time-intensive, do not offer the same level of accuracy, and are error-prone, thereby making them rather obsolete in today’s day and age of optical sensor technology that is flexible, accurate, and enables ecologically sustainable operations thereby bringing down your costs.

Conventional measuring systems also tend to fail in automated manufacturing processes because they just cannot keep up with the speeds. Today’s processes have become so fast they can no longer be ascertained by the human eye. Mechanical measuring methods do not support this speed, and therefore an alternative such as optical testing is possibly the best solution.

Benefits of Optical Testing

Clearly, modern manufacturing is being revolutionised by the use of optical testing not just in terms of improving current manufacturing capabilities but enabling new ones as well.

Here are some reasons optical testing is preferred:

- Light can be used in the remote probe or process of materials

- The use of optics minimises the possibility of contamination of product as there is no surface contact

- Optical testing does not cause wear and tear of the product

- Light can cast images, making it possible to inspect parts of the product to ensure consistent component fabrication

- Optical testing is used to monitor chemical processes in real-time

Types of Optical Testing Techniques

- Performing manufacturing:

Here, the optical testing mechanism interacts directly with the product. - Controlling manufacturing:

Here, optics aid in providing information about a manufacturing process or to inspect a manufactured product.

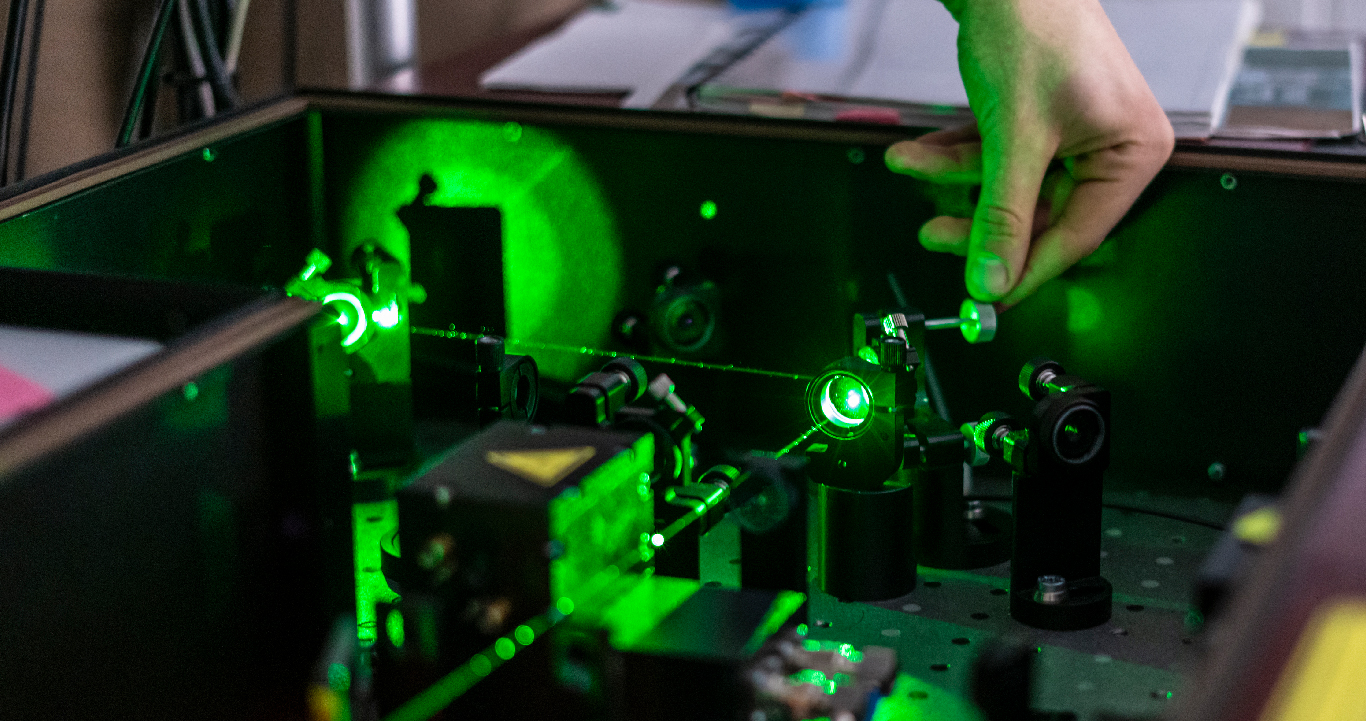

Optical sensors and laser-based test and measurement systems have proven to be game-changers in manufacturing, research, and production as they provide speed, control, precision, and accuracy.

The product portfolio at MELSS offers optical test measurement and simulation solutions for the research and development community in leading universities, academic, defence, space, and atomic energy institutions. MELSS also integrates several machine vision systems for inspection systems required in manufacturing and assembly. For more information, please visit www.melss.com