Advanced Indoor Air Quality Monitoring with Sixdime SWAS

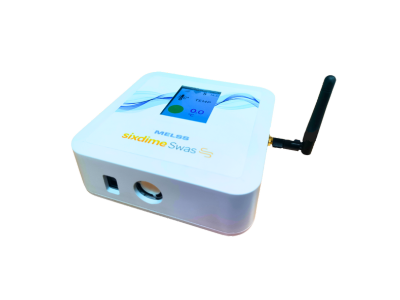

sixdime Swas is a high-precision indoor air quality monitoring device designed to measure particulate matter, VOCs, nitrogen oxides, temperature, and humidity. Engineered for industrial facilities, clean zones, and controlled environments, Swas provides accurate, real-time environmental data with WiFi, GSM, and Ethernet communication.

Why Choose Sixdime SWAS

sixdime Swas provides highly accurate environmental sensing with multiple connectivity options, making it ideal for compliance-driven industries. Its easy deployment and MELSS’ monitoring expertise ensure reliable and actionable data for industrial and commercial environments.

How sixdime Swas Works

sixdime Swas continuously measures key environmental parameters, including particulate matter, VOCs, NOx, temperature, and humidity. The device streams this data in real time via WiFi, GSM, or Ethernet to cloud platforms, dashboards, or local displays, enabling instant monitoring, alerts, and data-driven decision-making in industrial and commercial environments.

Multi-Parameter Sensing

High-precision sensors measure PM1.0, PM2.5, PM4, PM10, VOCs, NOx, temperature, and humidity, providing comprehensive environmental data.

Real-Time Connectivity

Data is transmitted in real time over WiFi, GSM, or Ethernet to dashboards, cloud systems, and alert interfaces for instant visibility and action.

Alerts & Insights

Visual and remote alerts notify operators and supervisors of environmental deviations, while historical data trends support analysis and compliance reporting.

Key Features

Technical Specifications

Particulate Matter

10μm (PM1.0, PM2.5, PM4, PM 10

Sensing Temperature

10°C to 50°C

Humidity

0 - 90 %

VOC and NOx Index

1 - 500

Sampling Interval

1 sample per second

Data Interface

WiFi/GSM/Ethernet 100BaseT

Visual Indication

2.4” Color OLED Display

Applications

sixdime Swas is suitable for a wide range of industrial and commercial environments, providing accurate, real-time air quality data for process-controlled and compliance-driven operations.

See It in Action – Sixdime SWAS

Watch how sixdime Swas provides real-time indoor air quality monitoring for industrial and commercial environments.

Case Studies

Transforming Operations Across Industries: Real Success Stories with sixdime MES

Smart Warehouse Optimization

Industry 5.0 brings a new dimension to automation by balancing advanced technologies with human creativity and well-being. Unlike previous industrial revolutions focused solely on efficiency, Industry 5.0 places the empowerment of people at its core—robots, AI, and IoT work alongside skilled professionals to achieve smarter and more sustainable production.

Read More →

The need for traceability

How can manufacturers ensure that every product meets quality standards and remains compliant with industry regulations? The answer lies in robust traceability systems. By tracking each stage of the production process, companies can quickly pinpoint and resolve problems, efficiently recall affected products, and confidently demonstrate compliance during audits.

Read More →

What is Poka Yoke?

Experience scalable production automation that evolves with your business—discover how mistake-proofing with Poka Yoke can lower downtime, streamline operations, and deliver reliable quality. Explore practical solutions that adapt to growth and help you overcome manufacturing challenges..

Read More →Ready to Monitor Your Environment?

Ensure safe and compliant indoor air quality with sixdime Swas – real-time monitoring for industrial and commercial environments, empowering you with actionable insights and alerts.

Request a Demo